The order picking process is one of the most important operations in warehouses and stores because it can affect more than half of warehouse operating costs, especially that the rapid execution of orders will affect customer satisfaction and thus increase their retention and avoid losses and additional costs, so it’s method is very important for your organization or Your company, and in this article, we will talk about the concept of order picking as well as the best methods.

What is order picking?

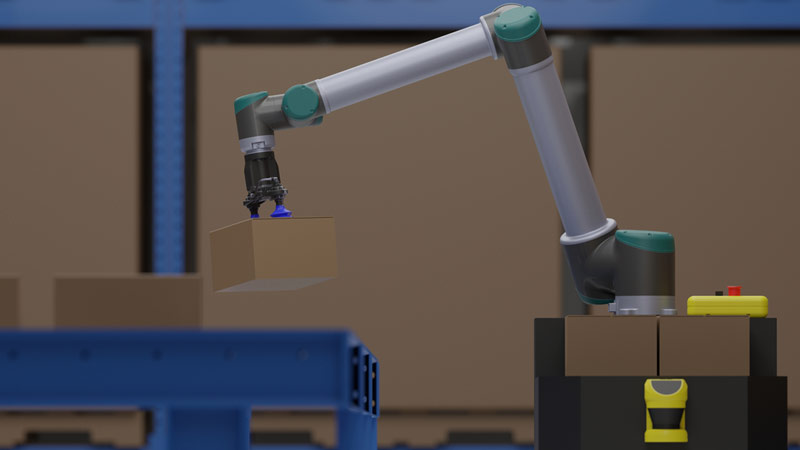

means the process by which products are retrieved from warehouse stock to fulfill customers’ orders, and it is one of the activities that require great accuracy as well as a large number of workers,

Especially since the time is taken in the order picking process will greatly affect the delivery time and thus customer satisfaction.

Order picking in the Warehouse

Order picking in a warehouse is the process in which the required items are selected from a fulfillment center that meets customer requests, and in fact, it is an activity that requires a lot of costs and requires labor-intensive in warehouses

Also, the costs of picking in a warehouse represent about 55% of the costs of the distribution center, and this process is actually one of the most important operations in any company.

Warehouse picking directly affects the satisfaction of your customers, as well as the reputation of the business and the brand you provide, as well as a direct impact on your profits and revenues as well.

Best Solutions for order picking

Warehouses can improve their systems by enhancing the productivity of their order picking, which will positively affect the efficiency of warehouses and thus customer satisfaction and the efficiency of the entire work.

And the following are the best order picking solutions:

- Keep your SKUs separately, which will help you reduce costs in searching for the right SKUs, and you can also specify a specific selection site for each SKU.

- Try to use group strategies when picking orders, which will reduce the time and help you choose more than one order in the same trip and thus increase efficiency, so it is one of the optimal order picking solutions.

- Enter the horizontal picking system, as it makes it easier to find the necessary items quickly, which will help you to reach the most requested items quickly, and the less requested items use the vertical system with them.

- Choose the right type of storage for items, thus reducing handling processes so items become fast-moving on the shelves, thus reducing restocking time, and this is one of the best order picking solutions.

- Collect frequently ordered items in the same area to make it easier to find, thus reducing time and speeding up the delivery process, even more, keeping customers highly satisfied.

you may want to know: Retail stores optimizing Inventory Management, Eases Ecommerce Implementations

Order picking methods

There is more than one method that is used in order picking, and the following are the most important of these methods in some detail:

1. Wave order picking

is one of the most popular methods in which workers are working in specific areas, and after selecting the ordered items they are sorted and then combined into their shipments.

This method helps reduce the time it takes to pick up requests, and it is better than selecting requests from a region and then aggregating at the end.

This method requires a larger number of workers and is more suitable for companies or institutions that have a higher number of picks per order

2. Cluster order picking

The second popular method is Cluster order picking, in which more than one order is picked at the same time so that workers pick a large group of items for multiple orders.

The most common method of this type is the use of a cart loaded with multiple containers, which keeps orders organized and reduces errors.

3. Zone order picking

In this method, the warehouse is divided into zones and each worker is assigned a zone to pull the required items from, then pass an order container into the next zone until the entire order is collected.

This method is the best picking method for large warehouses that suffer from overcrowding.

4. Pick and pass

It is another popular order picking method, in which warehouses are also divided but workers pick SKUs for multiple orders simultaneously within their own district.

Then the containers are passed to the next area, and sometimes the request can be completed without the need for any further passes.

5. Batch order picking

It is a multi-method, in which more than one order is worked on at the same time, which is the best way for companies or institutions that have multiple orders at the same time, and this method will reduce the time for selecting items in each picking cycle.

6. Single order picking

is the most used order picking method, but it is also the most time-consuming method in warehouses, as each worker in this method works on one order at a time.

will be suitable for those who have smaller warehouses that handle few daily orders.

Recent Comments